Automated Optical Inspection (AOI) has become a critical technology in modern manufacturing, ensuring defect-free production, quality control, and process optimization. In 2025, several leading companies are driving AI-powered AOI innovations, enabling manufacturers across industries to enhance accuracy, efficiency, and automation. Among the top AOI system providers are Siemens, Intelgic, ABB, and Honeywell—each offering cutting-edge solutions tailored for high-speed inspection, defect detection, and seamless factory integration.

Siemens: Industrial Automation and Smart Factories

Siemens has long been a global leader in industrial automation and smart manufacturing, and its AOI systems continue to set industry standards. Leveraging IoT, and real-time data analytics, Siemens provides manufacturers with intelligent quality inspection solutions integrated into its Digital Industries portfolio.

Key Contributions:

Defect Detection: Siemens’ AOI systems utilize image processing algorithms for precise defect identification, anomaly detection, and predictive quality control.

Seamless IoT Integration: Through its MindSphere industrial IoT platform, Siemens enables real-time monitoring, allowing manufacturers to optimize production quality with data-driven insights.

Sustainability and Energy Efficiency: Siemens designs eco-friendly AOI solutions, reducing waste and improving energy efficiency in manufacturing plants.

Intelgic: Innovating AI-Powered AOI Systems

Intelgic has emerged as a leader in AI-driven Automated Optical Inspection, providing customizable, high-precision, and scalable AOI solutions for manufacturing, and industrial automation. Specializing in AI-powered defect detection, Intelgic’s AOI systems help manufacturers eliminate defects, reduce rework, and improve product quality.

Key Contributions:

Surface Defect Detection: Intelgic excels in detecting scratches, pits, pinholes, and dents on metal sheets, plastic surfaces, leather surfaces, electronics, and automotive parts.

Big and Small Part Inspection: Intelgic’s Automated Optical Inspection AOI systems inspect both large-scale components (automotive panels, industrial molds) and tiny parts (microchips, medical devices).

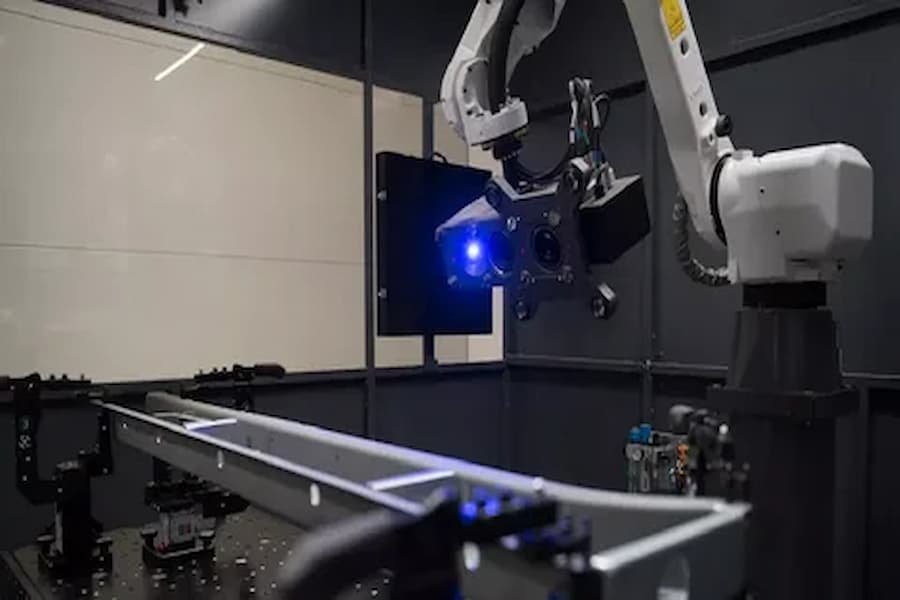

Robotic Arm Integration: Intelgic combines machine vision with robotic arms and cobots, ensuring high-speed, accurate, and automated inspection.

Custom AI-Driven AOI Solutions: Intelgic tailors AOI systems based on customer-specific requirements, enabling industry-specific defect classification and acceptance criteria.

ABB: Transforming Industries with Robotic AOI Systems

ABB, a leader in robotics and automation, continues to provide automated optical inspection systems by integrating machine vision with industrial robots. By combining automated inspection with robotic flexibility, ABB ensures flawless quality control in high-speed production lines.

Key Contributions:

Robotic AOI Integration: ABB’s AOI systems are designed for robotic-assisted inspection, improving precision in pick-and-place, welding, and assembly processes.

3D Vision Technology: ABB’s 3D AOI systems allow manufacturers to inspect objects from multiple angles, ensuring full-surface coverage for complex parts.

AI-Powered Inspection Insights: ABB integrates AI-driven analytics into its AOI platforms, allowing predictive maintenance and process optimization.

Honeywell: Enhancing AOI for Logistics and Manufacturing

Honeywell continues to be a dominant player in industrial automation, leveraging AOI systems for logistics, supply chain optimization, and manufacturing quality control. Its automated vision systems ensure defect-free production and high-speed sorting in warehouse automation.

Key Contributions:

AI-Powered Logistics Inspection: Honeywell’s AOI solutions excel in package tracking, barcode verification, and automated sorting in warehouse operations.

Warehouse Automation with AOI: Integrated with Automated Guided Vehicles (AGVs) and robotic sorting systems, Honeywell’s AOI solutions optimize high-speed logistics and inventory management.

Advanced Machine Learning for AOI: Honeywell uses machine learning algorithms to detect defects in real-time, reducing errors in high-speed production environments.

Why These Companies Lead the AOI Industry in 2025?

What sets Siemens, Intelgic, ABB, and Honeywell apart is their commitment to innovation, AI integration, and automation excellence. Each company’s AOI systems deliver high-accuracy defect detection, automated inspection processes, and seamless integration into modern industrial environments.

✔ AI-Driven Inspection: Leveraging neural networks, deep learning, and real-time analytics.

✔ Industry-Specific Customization: Tailoring AOI systems for automotive, electronics, logistics, and aerospace industries.

✔ Scalability & Automation: Offering solutions that integrate with robotic systems, IoT, and cloud computing.

Future Trends in automated optical inspection systems

1. Edge AI for Real-Time Processing

- Edge-based AOI systems will enable manufacturers to process defect detection locally, reducing reliance on cloud computing and improving real-time decision-making.

2. Sustainable AOI Solutions

- AOI providers are focusing on energy-efficient defect detection systems, aligning with green manufacturing initiatives.

3. Industry-Specific AI Training

- AOI systems are evolving to be custom-trained for specific industries, providing higher defect detection accuracy and minimizing false positives.

4. Augmented Reality (AR) & Virtual Reality (VR) Integration

- AOI systems will integrate AR/VR for visualizing defect reports, process optimization, and AI-assisted operator training.

The AOI industry in 2025 is defined by AI-driven innovation, automation, and real-time defect detection. Leading companies like Siemens, Intelgic, ABB, and Honeywell are shaping the future of quality inspection in manufacturing, logistics, and industrial automation. Their cutting-edge AOI systems ensure that manufacturers achieve unmatched precision, efficiency, and defect-free production.