Industrial water treatment systems are becoming increasingly complex as industries face stricter environmental regulations, higher efficiency requirements, and growing operational challenges. In this evolving landscape, innovation plays a crucial role in ensuring system reliability, safety, and long-term performance. Advanced engineering solutions are essential to optimize water treatment processes and protect critical equipment from damage or inefficiency.

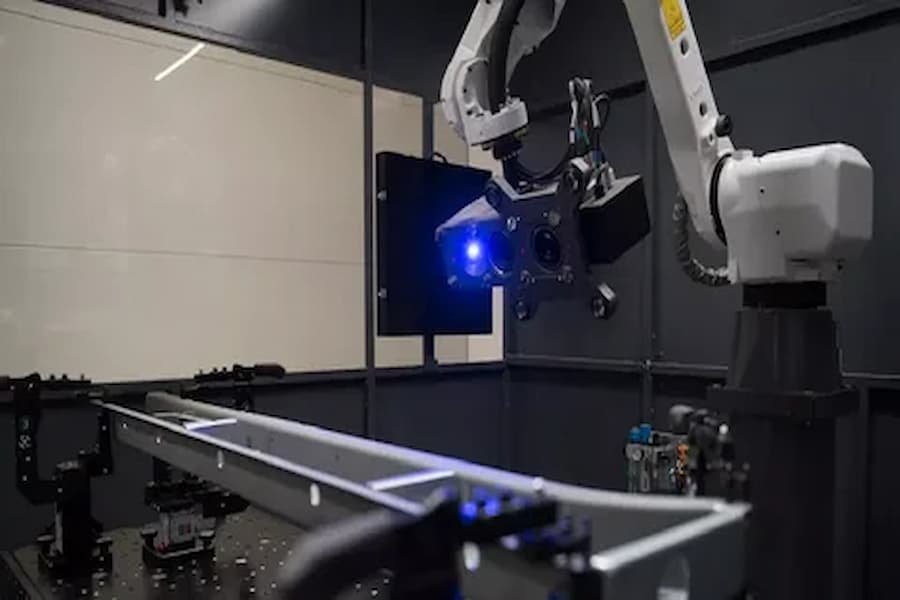

ILMAP operates at the forefront of this evolution, designing and manufacturing innovative solutions for produced water treatment. The company develops high-performance components such as filtering nozzles, distribution and drainage systems, safety traps, air diffusers, and a wide range of related accessories, all engineered to meet the demanding needs of industrial applications.

ILMAP’s Integrated Approach to Water Treatment Systems

Effective water treatment requires a holistic system design in which every component contributes to overall efficiency and operational stability. ILMAP adopts an integrated approach, ensuring that its products work seamlessly together within ion exchange and filtration systems. This system-oriented philosophy allows plant operators to achieve consistent water quality while reducing maintenance requirements and operational risks.

By combining durable materials, precise manufacturing, and application-specific design, ILMAP components are suitable for a wide range of industrial environments, including chemical processing, power generation, and industrial water reuse.

Ion Exchange Systems and the Need for Safety Components

Ion exchange technology remains one of the most widely used methods for removing dissolved ions from water in industrial processes. While highly effective, these systems rely on resin media that can be subject to mechanical stress, aging, or unexpected pressure fluctuations. Resin loss is a common issue that, if not properly controlled, can lead to serious operational problems.

Escaped resin beads can damage downstream equipment such as pumps, control valves, membranes, and sensors. These issues often result in unplanned downtime, increased maintenance costs, and reduced system efficiency. For this reason, incorporating protective safety components is essential for maintaining reliable operation.

The Importance of Resin Traps in Ion Exchange Applications

Resin traps play a critical role in protecting industrial water treatment systems. Installed downstream of ion exchange vessels, they are designed to capture resin beads that escape the primary containment. This simple yet effective safety measure prevents resin migration and safeguards sensitive equipment.

ILMAP resin traps used in industrial ion exchange water treatment applications are engineered to provide high retention efficiency without compromising hydraulic performance. Manufactured using robust materials and optimized filtration geometries, these traps ensure long-term reliability even under continuous operation. Their design allows for easy inspection, maintenance, and integration into both new installations and existing systems.

Complementary ILMAP Components for System Efficiency

In addition to resin traps, ILMAP offers a comprehensive range of components that enhance the overall performance of water treatment systems. Filtering nozzles are designed to ensure uniform flow distribution and effective media retention, contributing to consistent filtration and ion exchange efficiency.

Distribution and drainage systems are equally important, as they ensure balanced flow during service and regeneration cycles. Proper distribution improves treatment effectiveness, while efficient drainage supports thorough cleaning and regeneration of the media, extending system lifespan and reducing chemical consumption.

Air Diffusion and Operational Optimization

Air diffusers represent another key element in ILMAP’s portfolio. Used in various treatment stages, air diffusion systems improve mixing, oxygen transfer, and process stability. ILMAP air diffusers are engineered for durability and efficiency, helping operators reduce energy consumption while maintaining optimal system performance.

These components, when combined with safety devices such as resin traps, contribute to a stable and resilient water treatment infrastructure capable of adapting to changing operational demands.

A Commitment to Quality and Customization

What sets ILMAP apart is its commitment to quality, innovation, and customization. The company works closely with system designers and plant operators to develop solutions tailored to specific application requirements. This collaborative approach ensures that each component delivers measurable value and integrates seamlessly into complex industrial systems.

As industrial water treatment systems continue to evolve, the importance of reliable, well-engineered components cannot be overstated. Safety devices such as resin traps are essential for protecting equipment and maintaining operational continuity. Through its innovative product range and system-focused design philosophy, ILMAP provides advanced solutions that enhance efficiency, safety, and sustainability in industrial water treatment applications.